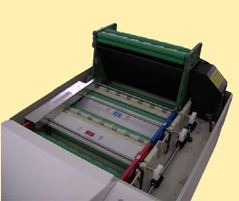

HQ - 350 XT X-RAY PROCESSOR

Технические характеристики

| Film Format | 10 x 10 cm minimum 35 x ∞ cm maximum |

| Film Type | Sheet or rollfilms |

| Film Source | X-Ray, CT, MRI medical film |

| Capacity, (in 90 sec process time) |

10 x 10 cm : 840 films per hour (3 Parallel)

18 x 24 cm : 258 films per hour (2 Parallel)

24 x 30 cm : 129 films per hour

35 x 43 cm : 70 films per hour

|

| Process Time | 90 sec — 160 sec |

| Develop Time | 25 sec – 45 sec |

| Solution tanks temperature control range | 28ºC - 38ºC |

| Dryer temperature control range | 50ºC - 65ºC |

| Replenishment rates | 400 ml/m2 |

| Replenishment Containers | 25 lt |

| Anti Cristallisation | Once in every 4 minutes |

| Anti Oxidation | While device is empty and oxidation proof cover |

| Tank Volume | Developer: 5.5 lt Fixer: 5.5 lt Water: 5.5 lt |

| Chemical Replenishment Mode | Autoamtic/Manual/ Continuous,during the process Automatic : Once after every film |

| Water Consumption |

2.0 lt/min (process)

0.0 lt/min (stand by)

|

| Mains | 220V±10% / 50Hz |

| Dimensions (L/W/H) | 86 x 58 x 52 cm |

| Net Weight | 35 kg (empty) / 60 kg (full) |

| Water Pipe Radius | 15 mm |

|

|

Lower costs for water and chemicals consumption with high efficiency and maximum energy .

|

|

|

With it’s small dimensions it is possible to use in small places. The footprint is only 0.36 m2.

|

|

|

Fixer and developer volume is only 5 . 5 L .

Whiledecreasing the replenishment time it keeps the chemicals in better condition.

• High quality and easy to find spare parts all over the world

• 2 year free of charge service guaranty (Production defects)

• Minimum ten years of spare parts availability

|

|

Output from both sides of the device is also possible. After loading the unprocessed film from the dark room, the output could be taken from other side in a light room.

|

|

|

While the covered film tray provides maximum safety, on the other hand it is also possible to use a microfilm attachment.

|

|

|

Full automatic and easy using experience via microprocessor based design.

|

|

|

The factors which are effecting the output quality can be set and fallowed with the control panel.

1. Developer temperautre (Set & Display)

2. Dryer temperature (Set & Display)

3. Developer and fixer replenishment speed (Set)

|

|

A common pump for the developer and fixer . Speed can be set and followed by the control panel.

|

|

|

In emergency cases, manual operation can be started in minimum 90 seconds even the device is not fully ready. Depending on the user maximum process time can be set up to 160 seconds.

|

|

|

Rustproof frame, process tanks and durable dryer guaranties problem free long life.

|